Miscellaneous: Difference between revisions

| Line 11: | Line 11: | ||

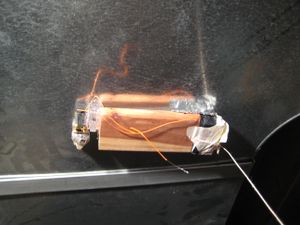

==The Slug (an experiment in fishing wires using scraps and tape) - 20190815== | ==The Slug (an experiment in fishing wires using scraps and tape) - 20190815== | ||

[[File:The-slug-01.jpg|thumb|Wire pulling machine for pulling wire under a metal duct.]] | |||

Today, I needed to fish some cable through my basement so we could have a decent internet connection in our garage. Part of the cable run consists of running a 20 foot length across a ceiling. The area I had to work with was about 2 inches high and a foot wide, (and 20 feet long) with no walls and no floor. You can't hold a 20 foot long stick horizontally in this orientation, nor can you easily push a fish tape through. However, directly above this area is a heating duct, which is magnetic. | Today, I needed to fish some cable through my basement so we could have a decent internet connection in our garage. Part of the cable run consists of running a 20 foot length across a ceiling. The area I had to work with was about 2 inches high and a foot wide, (and 20 feet long) with no walls and no floor. You can't hold a 20 foot long stick horizontally in this orientation, nor can you easily push a fish tape through. However, directly above this area is a heating duct, which is magnetic. | ||

Latest revision as of 06:24, 13 September 2019

NAP monochrome computer monitor - Power supply - 20190721

I found this new old stock monitor the other day for really cheap, but upon bringing it home and plugging it in, there was no activity - no flyback transformer sound and no power LED. This seems like it is some kind of power supply issue. The first thing I did was check the on board fuses, but both were OK. Inside the case, I found a transformer separate from the main PCB. My initial thought was that some of the low voltage power supplies come from the transformer, but it turns out that all power for the entire monitor is fed by one ~15vac secondary winding on the transformer. From there, I began to trace the power through the main PCB. The first thing that happens is that it goes through a full bridge rectifier and capacitor, making unregulated DC. Then, the power goes into a PNP power transistor, which is the largest heatsink on the board, connected to the base of this transistor was some other small transistors and resistors. My guess was that this was some kind of linear regulator implemented with discrete transistors. The output from the large PNP transistor would be some regulated voltage, which is the main voltage source for the monitor. I could tell where this power bus was because one side of the power LED was connected to it. After studying a bunch of schematics for similar monochrome monitors online, this does indeed seem to be the way that most of them work - while the monitor may run on 110vac, inside it's really running on a low voltage like 12vdc. Indeed, this did seem to be the case with my monitor. As a test, I bridged the power transistor so that unregulated voltage could make it over to the regulated side, then plugged the monitor into a variac and brought it up slowly. I observed that the filament began to glow, and I could hear the flyback transformer operating. After bringing up the monitor power to around 12V, I could see scanlines on the screen. The screen was very wavy from being on unregulated power, but I was happy to know that it worked. A further test with batteries and a video signal from a camera proved that the monitor worked as it should.

Back to the power problem: because I did not have the expertise or a schematic to fix the existing regulator, I decided that I would add in a regulator IC instead (I chose the adjustable LM317). I removed the existing PNP power transistor, and the supporting components used for its feedback. In a coincidence, I found that the footprint of the PNP transistor exactly matched the pinout of my new regulator IC, with the voltage In and Out pins aligning as is, and the Adjust pin being left free due to the removal of the supporting components. This also meant that I was able to reuse the heatsink to keep the regulator cool. Following the application note from the LM317 datasheet, I added supporting decoupling capacitors, and the adjustable voltage divider (fixed resistor and adjustment pot) needed to set the output voltage, to the PCB, although I did need to later move their locations after I discovered it interfered with the case geometry.

Finally, the monitor would work under its own power, but I had still had to set the output voltage from the regulator properly. But, what is the proper voltage? I knew it had to be less than 16V because all capacitors attached to the regulated voltage bus were rated no higher than that. The unregulated input voltage was only about 14-15V, which makes 12V seem too high. Indeed, once I completed it, my regulator would not even put out 12V even when the adjustment pot was turned up all the way. To resolve this, I tried to find the filament voltage of the CRT, which is pretty much wired directly into the regulated voltage supply. The CRT type is an M31-350LA/P, and no data exists about it on google. After a lot more searching, I eventually found a listing for a M31-359 crt from an old test equipment manual, which listed a M31-350 CRT with a filament voltage of 11V. That seems pretty reasonable given what I have experienced so far, so I set my regulator such that the CRT filament had 11V across it. Monitor now works great.

TRS-80 Model 1 power switch

I can't remember if I have listed this somewhere else on this site, but in mt TRS-80 adventures I experienced that my Model 1 did indeed have a broken power switch. The power switch on these machines are a plunger-type latching push button. Sometimes, the switch would not make contact when pushed in, and you would have to tap on it to get the power to turn on. Quickly though, the switch began to wear out until it was completely open whether pressed in or not. The switch would also get stuck, probably from the design of the latch itself binding up and not the contacts welding together, although I do think that excess inrush current contributes to the switch contacts wearing. Apparently, this is a common problem, because replacement switches are being sold on eBay - for $50 each. That's pretty steep for a switch, granted, these appear to be new old stock. But I could swear I have seen this design of switch before, so I tried to find a modern replacement. I seem to remember that I only found one suitable replacement on Digi-key, the F4UEE manufactured by C&K Components. These are still current parts, and have actual ratings for current and lifetime unlike a generic Chinese switch, so this shouldn't be some kind of cheap hack and should serve as a good replacement. It's a perfect fit in place of the old switch, but after using the computer like this for just a few days I found that the new switch developed exactly the same issues of binding and not making a perfect connection every time. Seems that Radioshack's design is the fault here, but at least the new switch does work (better than the old one which quit working altogether). I have some extras which I may replace this switch with in the future, but I'll save that for when the switch completely wears out, as it works well enough for now. Perhaps when that time comes I'll do a teardown and see what went wrong.

The Slug (an experiment in fishing wires using scraps and tape) - 20190815

Today, I needed to fish some cable through my basement so we could have a decent internet connection in our garage. Part of the cable run consists of running a 20 foot length across a ceiling. The area I had to work with was about 2 inches high and a foot wide, (and 20 feet long) with no walls and no floor. You can't hold a 20 foot long stick horizontally in this orientation, nor can you easily push a fish tape through. However, directly above this area is a heating duct, which is magnetic.

With little other options, I thought I would try to make a little crawler vehicle that would stick onto the duct and crawl the 20 feet upside down. I went and found a tiny gearmotor from an old project and grabbed the nearest battery, which was a 9 volt. A scrap piece of wood served as the body, with several magnets inset into it with the drill press. Then, I tried to find some wheel-shaped objects to use as wheels. The drive wheel was just a wood dowel covered in silicone tape for traction, with a hole drilled into it so it could be pressed onto the gearmotor shaft. I used some ball bearings for the idler wheels. The rest was held together with hot glue and tape, with a string attached to pull through, and allow me to pull it back if it got stuck.

The first version did not work very well. Because the duct is uneven, the car moves unevenly over it, often becoming stuck at the first bump. One of the big problems was keeping enough downforce on the drive wheel so it would have enough traction. Eventually, I decided to just tape some magnets around the drive wheel so it could grip the duct directly. The resulting wheel was no longer round, but did a much better job of griping the duct. The drive wheel could now traverse the seams in the duct, which seemed very promising for making it to the other end of the 20 foot run. However, I found that back end of the car did not do much anymore; the magnets were much weaker than the drive wheel's, and as I added more and more tape, the rear wheels no longer contacted the duct. So, I removed the rear wheels and replaced them with another magnet covered in slippery tape, which the drive wheel would just drag along the duct.

After a whole lot of false starts and adjusting things so that the thing would go in a straight line, I eventually got the device to crawl just over halfway through before getting stuck, which was close enough for me to reach in with a long stick with a magnet on it (which just barely reached it) and pull it through, along with the attached string. Probably wouldn't have been easier any other way, at least not with the materials on hand.